|

상세 정보 |

|||

| 외부 치수: | W600 × D600 × H1000 (MM) | 에어샤워 구역: | W400 × D420 × H400 (MM) |

|---|---|---|---|

| 맞춤 제작: | 지원하다 | 공식 사이트: | www.ffu-cleanroom.com |

| 인증: | ISO,CE,UL,RoHS | ||

제품 설명

![]()

기술 사양

| 분류 | 사양 |

|---|---|

| 모델 | AeroSeal TriFlow-TS300 |

| 표준 크기 (W x H) | 600mm x 600mm, 800mm x 800mm, 1000mm x 1000mm (개인용 크기가 가능합니다) |

| 문 작동 | 전기 3부위 수직 승강기, 모터로 구동되는 |

| 활성화 | 양면 누르기 버튼, 적외선 센서, 발 페달 또는 키 스위치 |

| 잠금 시스템 | 기계적 및/또는 전기적 잠금으로 두 개의 문이 동시에 열리지 않습니다. |

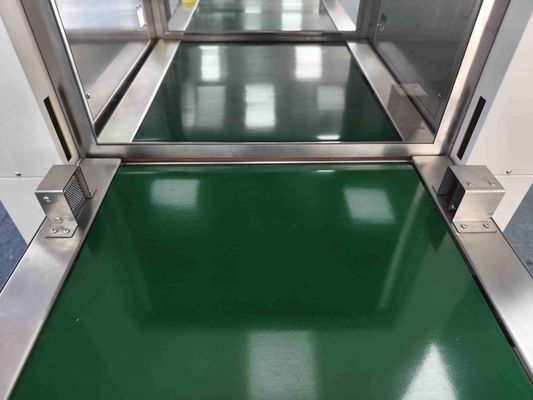

| 컨베이어 타입 | 가동 롤 컨베이어 (표준); FDA가 승인 한 벨트 컨베이어 (선택) |

| 컨베이어 부하 용량 | 최대 50kg (110lbs) |

| 건축물 | 304 또는 316L 스테인리스 스틸 (끝: # 4 붓 또는 전기 닦은) |

| 보기 창 | 열 분해 및 응축 방지용으로 두 장 판 템퍼드 글라스 |

| 밀폐 | 모든 문과 프레임에 실리콘 또는 EPDM 밀착 |

| 전원 공급 | 110V/220V, 50/60Hz (설정 가능) |

| 제어 인터페이스 | IP65 등급 터치 스크린 HMI, 사이클 카운터 및 진단 알림 |

| 옵션 | UV-C 살균 램프, HEPA/ULPA 필터 팬 유닛, 레이블 프린터 통합, BMS 통신 포트 (Modbus, BACnet) |

신청서

이 진보된 통과 창은 분리와 불균형이 가장 중요한 산업에 매우 중요합니다.

-

의약품 및 생명공학:A/B/C/D 등급 부위 사이의 부품 전송

-

의료기기 제조:제어된 환경을 통해 움직이는 부품과 조립된 장치

-

병원 약국 및 화합물:재료와 준비된 IV 봉투를 ISO 5급 격리장이나 후드로 안전하게 옮기기

-

식품 및 음료 생산:높은 관리와 낮은 관리 환경에서 위생 구역을 유지합니다.

-

전자 및 마이크로 전자:민감한 부품의 조립 과정에서 입자 오염을 방지합니다.

-

실험실:다른 격리 수준 실험실들 사이에서 샘플을 처리하는 것.

작동 방식 (프로세스 흐름)

-

부하:A쪽에서 작업자가 내부 컨베이어에 물건을 올려놓습니다.

-

시작:주기는 센서, 버튼 또는 페달을 통해 시작됩니다. A 측면 문이 닫히고 밀폐됩니다.

-

이전:내부 컨베이어는 자동으로 작동하여 물품을 방의 중심으로 이동시킵니다.

-

수신:컨베이어 가 멈춘 후, 인터클로크 가 풀려서, B 면 에 있는 운영자 가 문 을 열고 물건 을 가져오게 된다. 문 들 은 동시에 열 수 없다.

-

반환:빈 컨베이어는 A 쪽으로 돌아가거나 다음 화물을 기다리기 위해 작동할 수 있습니다.

왜 우리 의 '파스 트루' 창 을 선택 합니까?

-

신뢰성을 위해 설계된:산업용 부품으로 만들어져 24시간 운영이 가능합니다.

-

사용자 정의 가능한 솔루션:우리는 당신의 정확한 프로세스 요구에 맞게 다양한 크기, 재료 및 옵션을 제공합니다.

-

글로벌 컴플라이언스:cGMP, GAMP 및 기타 국제 규제 표준을 충족하도록 설계 및 테스트합니다.

-

전문가 지원:저희 팀은 설계 및 설치부터 검증 및 유지보수까지 모든 서비스를 지원합니다.

![]()

![]()